A diesel for the Rover SD1. At British Leyland this was suggested for

years and as well the public called for it. Yet caution had to be taken:

to simply put any diesel engine in the gorgeous limousine would ruin the

image of the Rover brand as a distinguished, innovative and avant-garde

car manufacturer.

For Rover a compromise like a petrol engine with diesel-like fuel

consumption and accompanying performance or a tuned conventional diesel

engine with slightly more BHP was out of the question. Rover had to find

themselves a worthy diesel, in fact a super diesel.

Therefore Rover started investigating their options and in the end they

chose an engine built by VM, an Italian company of the Iri-Finmeccanica

group. At VM they found a very modern design diesel engine, built for

using a turbo compressor. It was as robust as a traditional diesel but

light and powerful enough to resemble a normal petrol engine.

Under these conditions the cooperation between Rover and VM, between

elegance and reliability, between aerodynamics and avant-garde

technology, was simply unavoidable.

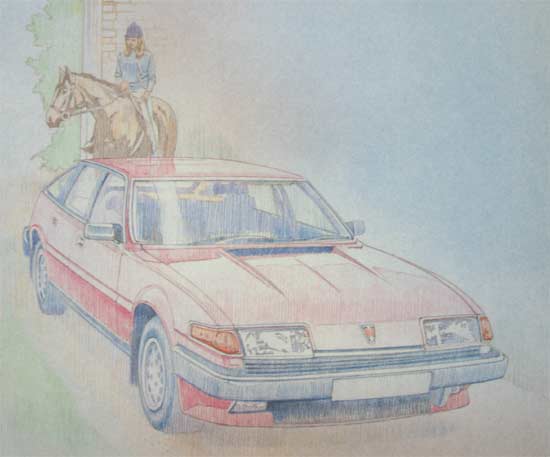

The 2400 SD Turbo is the sprout of this rare marriage.

This extraordinary car didn't go unnoticed by the public. Everyone that

had anticipated the Rover diesel was rewarded even better than their

expectations. Space, luxury that was the same as on the 2600 S and

reliability fully met Rover standards.

This same can be said for the vehicle in general. The decision for a

diesel engine was no pretext that a large elegant limousine can drive

cheaper as well. The 2400 SD Turbo is now generally seen as the most

modern diesel of its time, a real alternative for a petrol engine car

instead of a sorry excuse for it.

The choice for the VM-engine combined with the aero dynamical and well

built car leads to good performance, not only in the field of fuel

consumption. 6 Litres of diesel suffice for driving 65 miles at a

constant speed of 60 mph. Moreover the car performed very well on the

field of speed and acceleration. With its top speed of 165 km/h it was

the fastest diesel of its time and it could drive a kilometre from

standing still in 37,7 seconds.

A real European cooperation.

The Rover 2400 SD Turbo evolved from a cooperation of two large

companies in the field of car manufacturing, one English and the other

Italian.

The cars were built in Cowley, close to Oxford, where the engines came

from the VM factory in Cento, Ferrara Italy.

This engineering collaboration between Rover and VM was a real step

forward in the striving towards close European industrial cooperation.

The Italian heart of the Rover diesel.

Its type name is'HR 492 HT'.

It is a turbo diesel engine, which VM built for the five door Rover SD1.

The abbreviation stands for the following:

HR means High Revolution,

4 cylinder,

a 92 mm bore,

H stands for water cooling

and the T for the turbo.

VM started work on the HR engine series just after the Kippur-crisis

with the objection to find a modern answer to energy problems. Lots of

investigations and attempts were carried out in this time, both for

petrol engines as for diesel ones, all with the same goal of reducing

fuel consumption.

The HR engine was in fact the first where this modern technology was put

to use.

Other achievements have been acquired against nature's natural drawbacks

of the heavy sturdy diesel.

In some cases a clever but simple conversion of a petrol engine was

realised but much more was attempted to improve diesel performance by

applying turbo compressors.

With the HR engine VM had set very ambitious goals:

a diesel of the newest generation, which was designed for use with a

turbo from the initial design.

A very robust design that was built according to industrial stationery

engine production tolerances, cutting edge design solutions which should

lower the traditional engine weight close to that of a petrol engine and

patented innovations decreasing engine vibration and silencing the

dreadful diesel sound.

The HR series consists of 3, 4, 5 and 6 cylinder engines, each in two

capacity versions of either 500 or 600 cc per cylinder.

In total the series consists of 8 engines with indirect injection using

a Ricardo Comet V pre-chamber.

The engine used in the Rover is a four cylinder with 600 cc per

cylinder, making a total capacity of 2393 cc.

The common denominator or the HR engines is their modular structure. All

engines have been designed as multiples of each other.

A tunnel in the direction of reducing energy

consumption.

Two further important characteristics of the HR engine are the tunnel

shaped block and the separated cylinder heads. The block is built

entirely from cast iron, in which a tunnel for the crankshaft is left

open. The usual main bearing caps that support the crankshaft are

integrated in the engine block.

In the direction of the sump the engine has five barriers in between

each cylinder. Through these barriers runs one single tunnel in which

the crankshaft is built in. The crankshaft in its turn is supported by

five strong aluminium main bearings. These bearings are in no way

connected to the tunnel. With the engine running the expansion of the

aluminium being three times greater than that of steel presses the

bearing tightly to the block. And that's not all that happens. The thick

layer of aluminium between the crankshaft and the iron block is a

perfect 'sandwich panel' to reduce engine vibrations and noise. The

barriers mentioned earlier run into the oil in the sump muffle

vibrations effectively and add greatly to the stiffness of the block.

The cylinder heads are made of aluminium and are fully separated.

They are absolutely identical and interchangeable pieces. This makes

them harder to produce but is a key factor in making a strong reliable

engine.

The greatest problems with this engine were deformation of the cylinder

heads and their seals.

To attach the heads to the block the way of greatest freedom was chosen:

every single cylinder head can expand in every direction, without

raising pressure on the cylinder block and expand separately from the

other cylinder heads.

The result being a diesel engine that will pass any heat/stress test

without problems. It should be noted here that during heating up the

difference in expansion between a single cylinder head and the head of

the cylinder block exceeds 1 millimetre!

Designed for a turbo.

When the use of a turbo is already taken in to account in the early

stages of the engine design there will be no limitations in performance.

Any limitation will be merely caused by cost issues. If on a lean burn

engine performance is pushed with a turbo this will lead to a mixture

getting leaner with about 10-15%.

On a petrol engine this will eventually lead to detonation effects

and bad efficiency, yet on a diesel engine the turbo only brings

advantages with it. Fuel consumption, emissions, cylinder head

temperature, performance and even cycle life will benefit. But only, and

this must be made very clear, when the use of a turbo was taken into

account in the design of the engine.

In the case of the Rover engine the surplus of air reaches 0,85 bar,

i.e. per cylinder 85% more air is sucked in as on an atmospheric engine.

If the heating of the intake air in the turbo is taken into account, the

surplus will be around 60%. Yet the increase in fuel flow is limited by

30%. Fuel therefore burns with a surplus of air, which in the case of a

diesel engine lowers burning temperature, and improves fuel consumption

and emissions. Increase in performance is 45% and is purely powered by

exhaust gasses. The applied KKK turbo compressor K24 extracts some 12

BHP from the gasses.

Further advantages of a properly designed lean burn engine are further

reduction in engine noise, both at air intake as at the exhaust

manifold, a reduction of heat stresses in the cylinder, which is a

critical issue on most diesel engines, and equal performance at altitude

differences.